Tool Holders

Choose your tool holder →

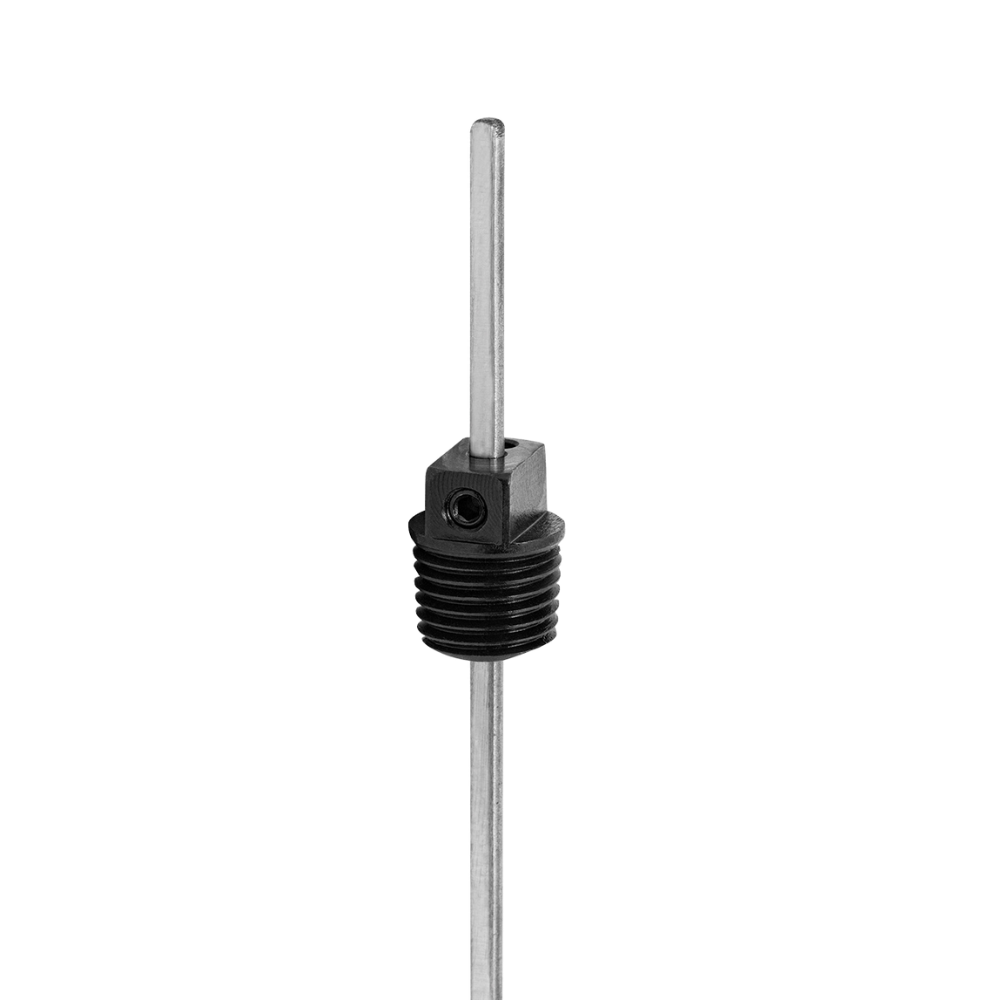

DH Holders

Dial in reach and rigidity for demanding applications with dependable clamping and consistent alignment

Features two lock-down screws

Available with or without flat

QHC Holders

Quick-change convenience with inch and metric options, plus a backstop for repeatable stick-out and faster changeovers.

Features three lock-down screws

Coolant through option

CRT (Coolant Ring Technology)

Holders

Coolant Ring Technology plus a removable backstop for repeatable setup and controlled coolant delivery

Features two lock-down screws

Coolant flow surrounds the tool for maximum cooling

Frequently Asked Questions

Q: What is the difference between CRT, DH, and QHC holders?

A: CRT holders combine Coolant Ring Technology with a removable backstop for repeatable setup and controlled coolant delivery. DH holders are built for secure clamping and alignment, with flat and without-flat options to match your setup needs. QHC holders are designed for quick-change convenience, offered in inch and metric, with a backstop option for consistent stick-out.

Q: Which holder should I choose if setup repeatability is my top priority?

A: If you want consistent stick-out and fast, repeatable setups, start with:

CRT holders (removable backstop + coolant ring)

QHC holders with backstop (repeatable stick-out + quick change)

DH holders are a great choice when your priority is a stable, secure setup and you need the right flat/no-flat configuration for your application.

Q: What’s the benefit of Coolant Ring Technology on CRT holders?

A: Coolant Ring Technology helps deliver coolant more effectively to the cutting zone, supporting heat control and chip evacuation. It’s especially useful when you’re trying to improve consistency and reduce tool wear in demanding applications.

Support That Starts

Before the Cut

We don’t just sell tool holders. We back them with the knowledge and support you need to meet spec and machine with confidence. Whether you’re refining your tool holding strategy or need speeds and feeds for a current job, these resources are here to help.

DXF and STEP File Downloads. Get CAD-ready files for faster CAM programming and toolpath simulation.

Explore Our Tech Support Pages. From troubleshooting tips to feeds and speeds guidance, our Technical Support hub is your go-to resource.

Still need help? Our in-house engineers are just a click away. Submit a question and we’ll get back to you quickly.