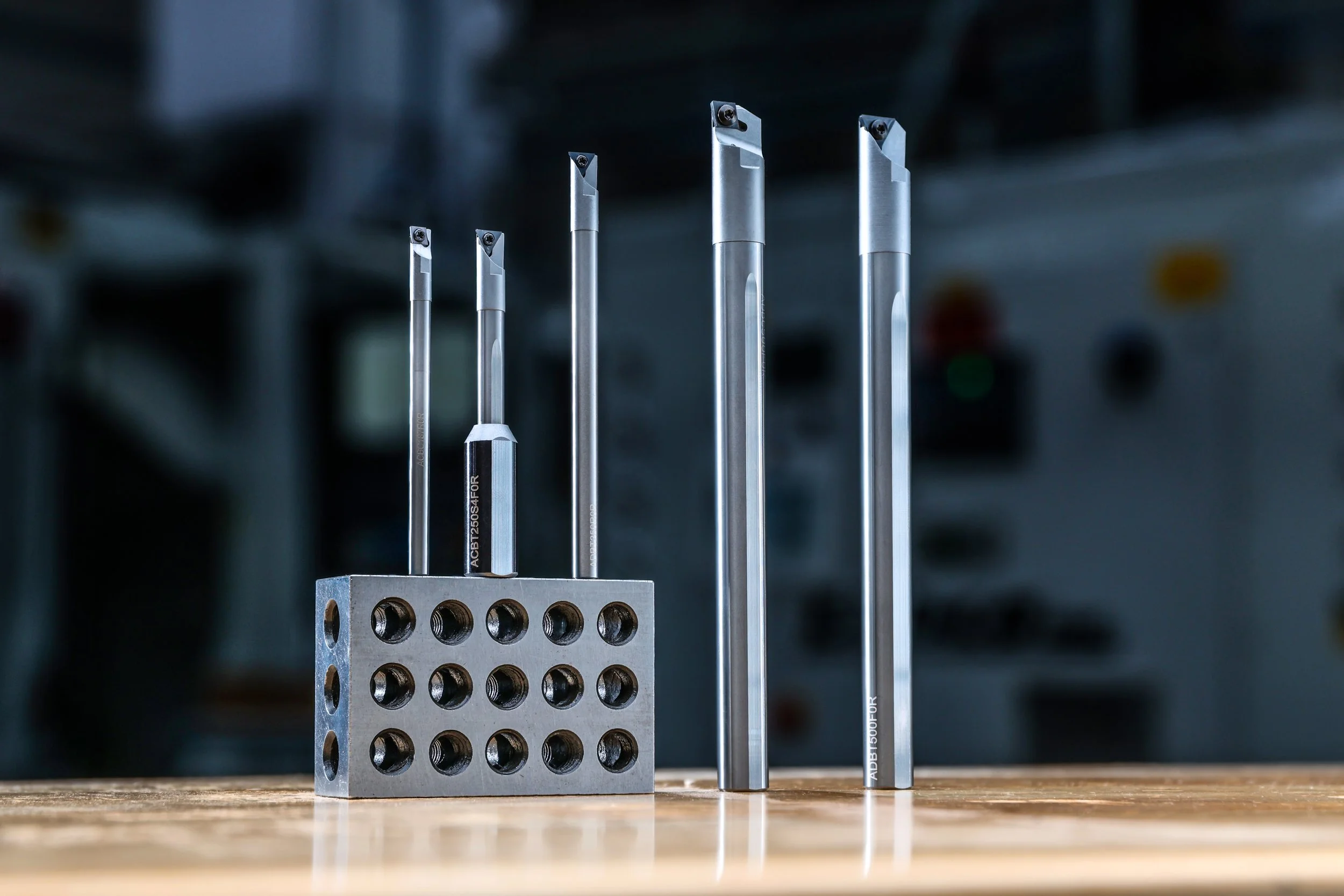

Indexable Boring Tools

Rigid, repeatable boring solutions for consistent size, finish, and insert changes

Designed specifically for small to mid-size bores. Choose triangle or diamond insert styles, with solid-body or coolant-through options to match your setup.

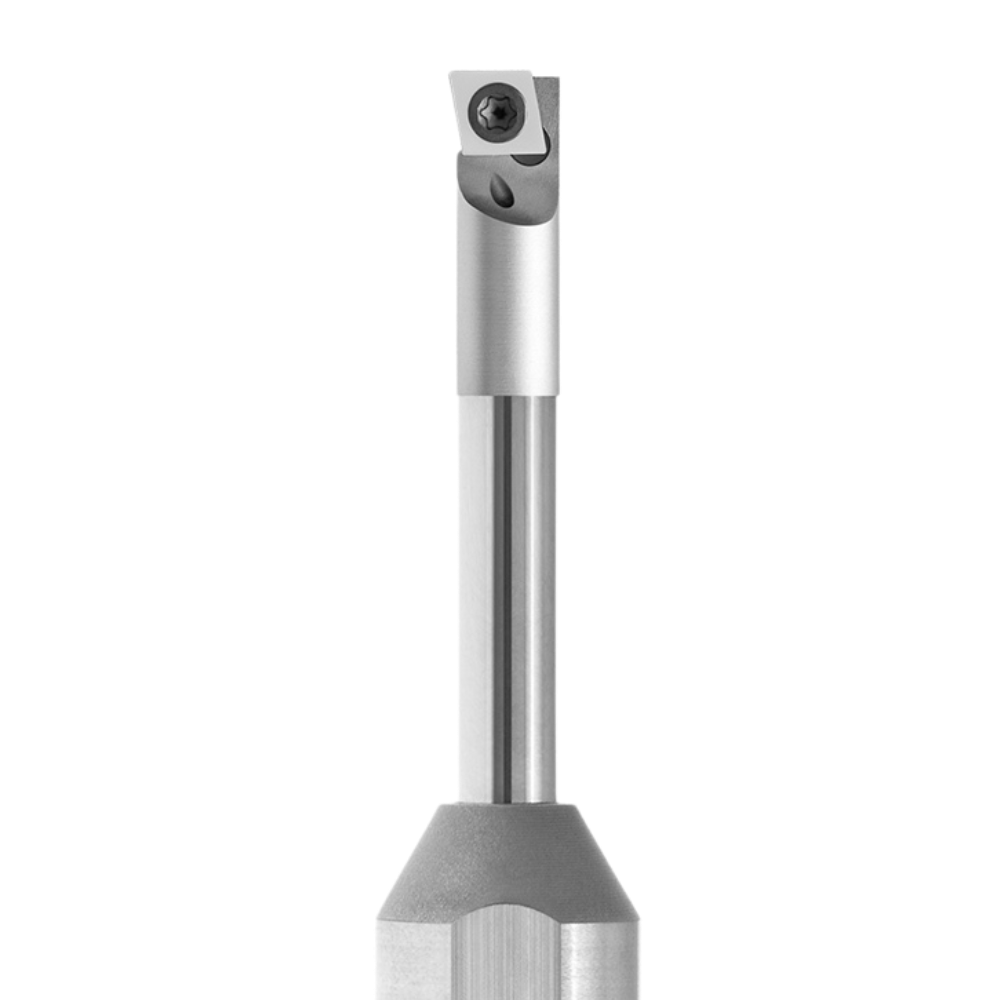

Bars for Diamond-Shaped Inserts

Stable, general-purpose 80° diamond insert platform for common boring work

Coolant-through and non-coolant options to match

your setup and chip control needsFlat or round shank styles available for your toolholder preference

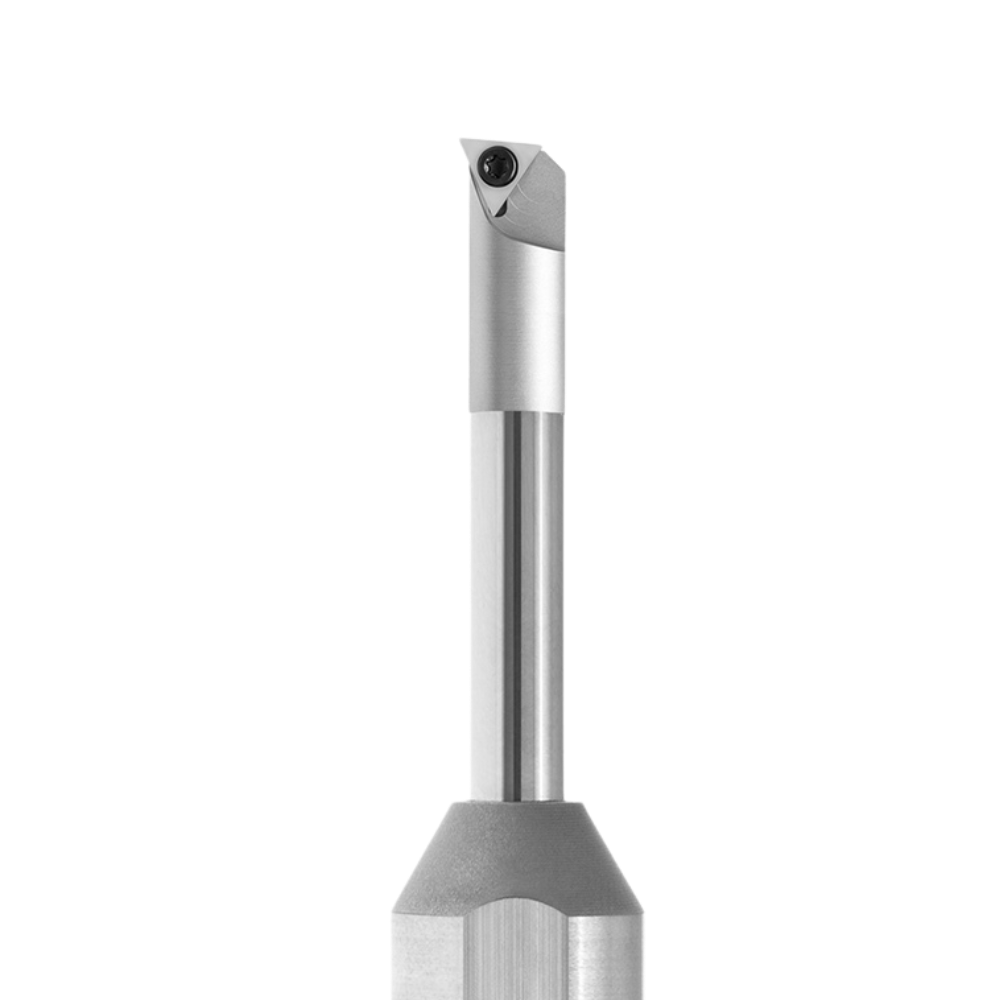

Bars for Triangle-Shaped Inserts

60° triangle insert platform for controlled boring in small to mid-size diameters

Coolant-through and non-coolant options available for improved chip evacuation

Flat or round shank styles available to fit common setups

Step Bars for

Diamond-Shaped Inserts

Stepped geometry provides added clearance for tight bores and shoulders

Helps reach into features while maintaining a compact, rigid setup

Available to match diamond insert styles for consistent indexing and support

Step Bars for

Triangle-Shaped Inserts

Added clearance for multi-diameter work, tight

access, and shoulder reliefCompact reach solution that supports stable cutting

in confined spacesDesigned to pair with triangle insert systems for consistent seating and indexing

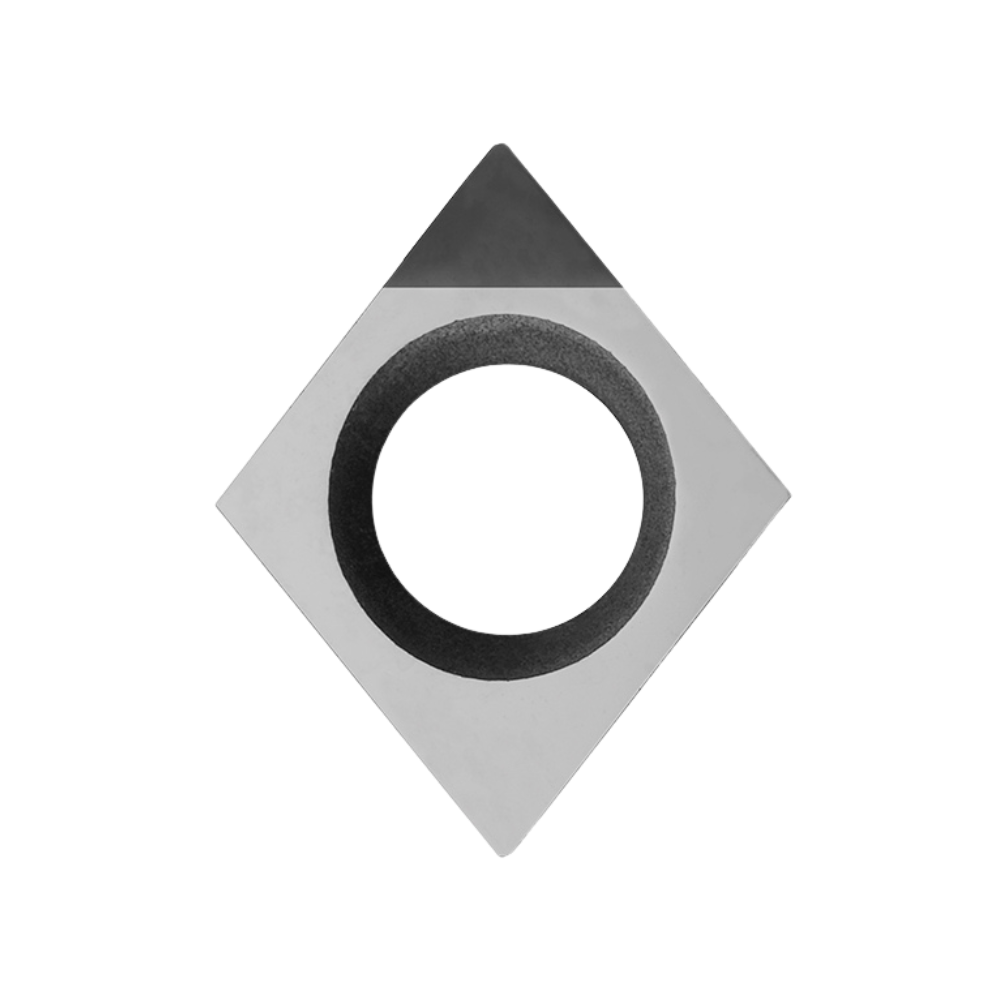

Inserts

Multiple insert styles to match your material and finish goals

Options include flat top, chip control, and PCD or

CBN tipped insertsBuilt for consistent seating and reliable performance across the boring system

Accessories

Replacement screws and flag-style Torx keys to keep bars running correctly

Correct torque and consistent insert seating help protect tool life and finish

Sized to match common bar families for quick, hassle-free maintenance

Support That Starts

Before the Cut

We don’t just sell indexable tools. We back them with the knowledge and support you need to meet spec and machine with confidence. Whether you’re refining your machining strategy or need speeds and feeds for a current job, these resources are here to help.

DXF and STEP File Downloads. Get CAD-ready files for faster CAM programming and toolpath simulation.

Explore Our Tech Support Pages. From troubleshooting tips to feeds and speeds guidance, our Technical Support hub is your go-to resource.

Still need help? Our in-house engineers are just a click away. Submit a question and we’ll get back to you quickly.