Porting Tools

Cut Ports that Seal Right the First Time

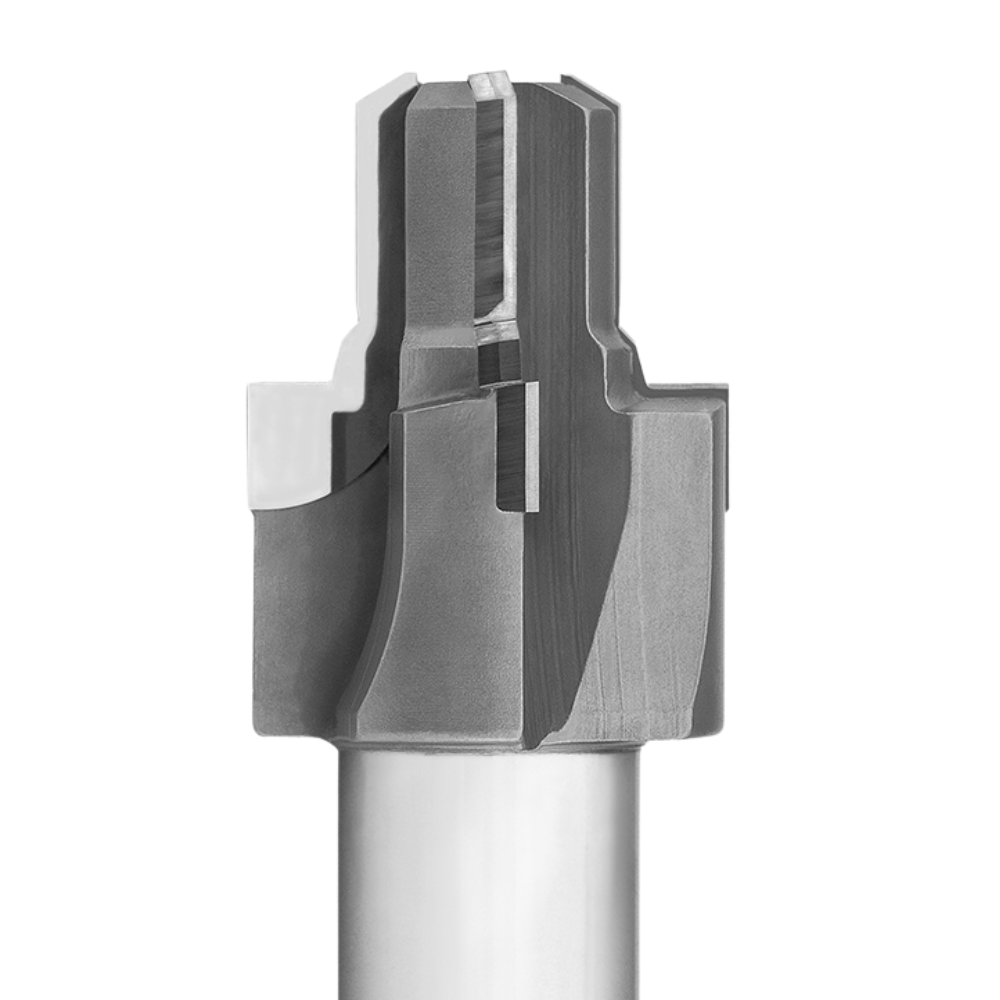

You need clean, consistent ports that meet spec and hold pressure. Scientific Cutting Tools designs solid carbide and carbide‑tipped port tools with polished flute faces for smooth finishes, excellent chip control, and repeatable accuracy. Many tools are available with coolant‑through designs and a variety of coatings are available to extend tool life in challenging materials.

Shop by port spec →

AS5202

UNJ thread callout and aerospace geometry per MS33649

Options: solid pilot, reamer pilot, and pilotless

Ideal for aerospace hydraulic and fluid power assemblies

SAE J1926

Straight thread O‑ring boss port geometry per J1926/1 and MS16142

Options: Solid pilot, reamer pilot, and pilotless

Ideal for automotive hydraulic and fluid power assemblies

Port Kits

Curated kits that cover AS5202 and SAE J1926 specs

Each kit includes a drill, a porting tool, and a 15° helical thread mill

Streamline the porting process with all three tools on-hand

Rosan Cavity

UNEF thread callouts for aerospace Rosan cavities

Meets requirements for PS10035, AS1300, AS4201, and 6M152

ISO 6149/1

Metric straight thread O‑ring port geometry

Common in mobile hydraulics and

diagnostic portsSupports adjustable and non‑adjustable

stud end styles

MS33514

Flareless tube connection and gasket‑seal seating geometry

Held to aerospace tolerances for repeatable assembly

Carbide‑tipped for durability in hardened materials

AND10050

Bosses with gasket‑seal straight thread dimensions

Stable cutting in non‑standard minor diameter lengths

Tapered Pipe Reamer

Preps holes for tapered pipe threads like

NPT and NPTFSmooth entry, accurate taper, and

controlled chip flow

Autoclave

Cone and thread port geometries for

medium and ultra‑high pressure systemsEngineered for extreme pressure service

with clean sealing surfacesOptions to suit Parker Autoclave style connections

ISO 1179

Ports with ISO 228‑1 threads for

elastomeric or metal‑to‑metal sealingCommon on industrial hydraulics and

general fluid powerSupports S and L series stud ends

MS21921

Seating geometry for tube coupling

nut interfaces45° seat features and tight

concentricity controlBuilt for aerospace hydraulic

assemblies

MS33651

Counterbore and minor diameter finishing

in a single setup45° included angle with small corner radii where specified

Polished flute faces for superior surface finish

Wondering which Porting Tool to use?

This video explains the key differences between porting tool options and how to know which one you should use.

Bradley Thomas, Marvel Machining

“SCT had the exact porting tool I needed and verified the port spec on the spot. Customer support for speeds and feeds made it super easy to run.”

Support That Starts

Before the Cut

We don’t just sell port tools. We back them with the knowledge and support you need to meet spec and machine with confidence. Whether you’re refining your porting strategy or need speeds and feeds for a current job, these resources are here to help.

DXF and STEP File Downloads. Get CAD-ready files for faster CAM programming and toolpath simulation.

Explore Our Tech Support Pages. From troubleshooting tips to feeds and speeds guidance, our Technical Support hub is your go-to resource.

Still need help? Our in-house engineers are just a click away. Submit a question and we’ll get back to you quickly.