Grooving Tools

Precision grooving tools engineered for consistent widths, clean walls, and confident chip control in internal operations.

Made in the USA and built for production reliability.

Choose your grooving tool type →

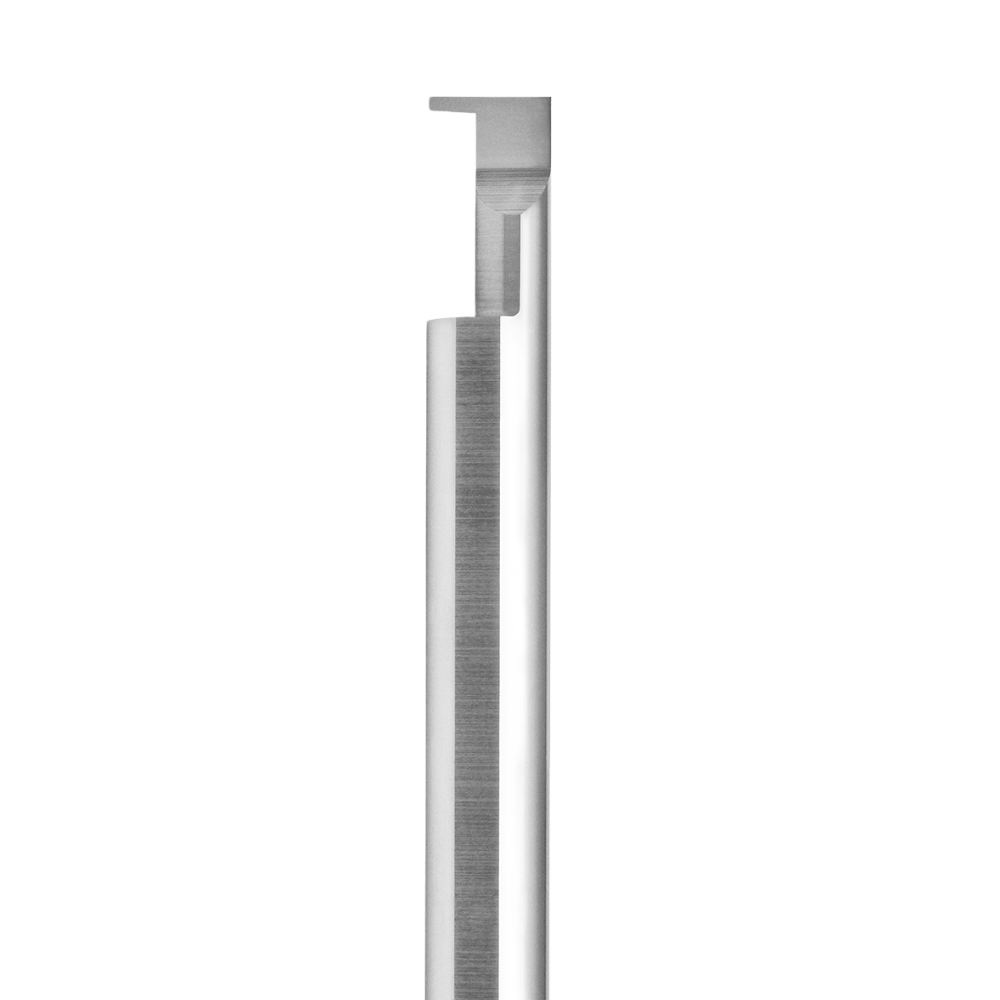

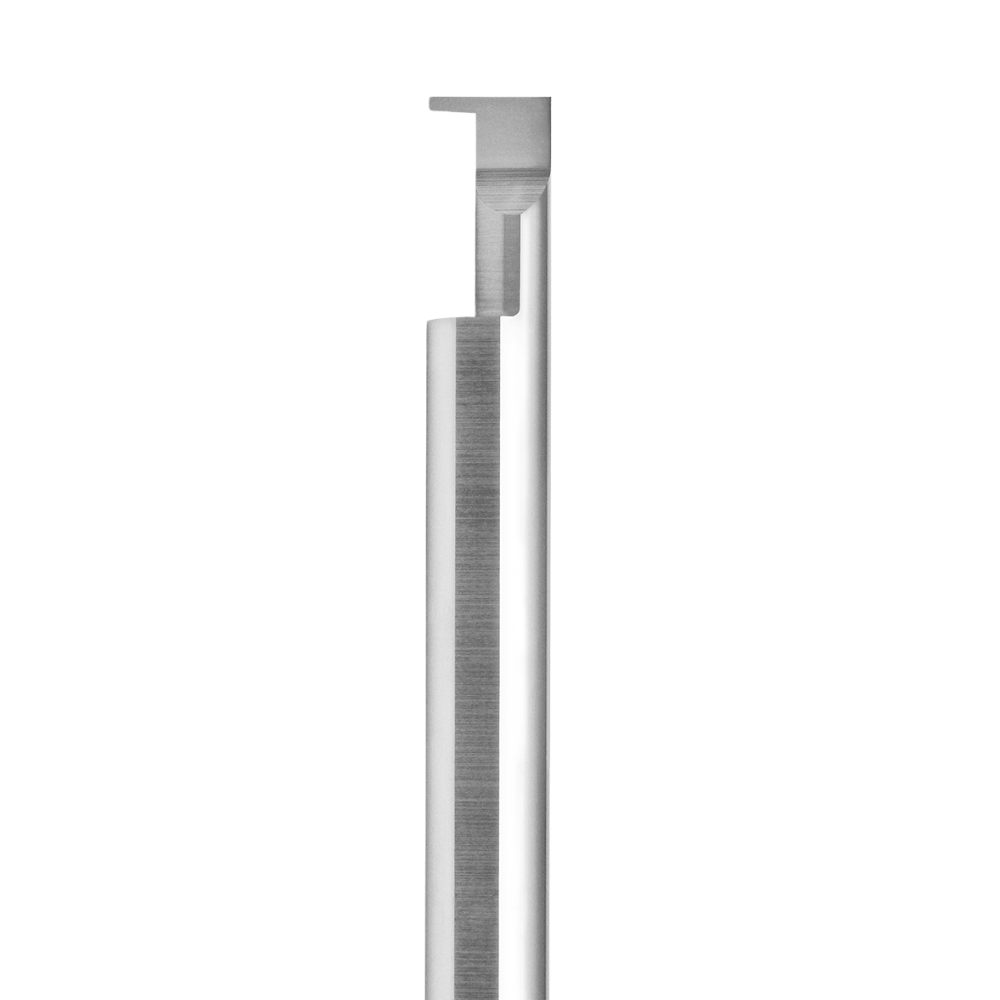

Retaining Ring

Groove Tools

Cut clean retaining ring grooves with predictable width control.

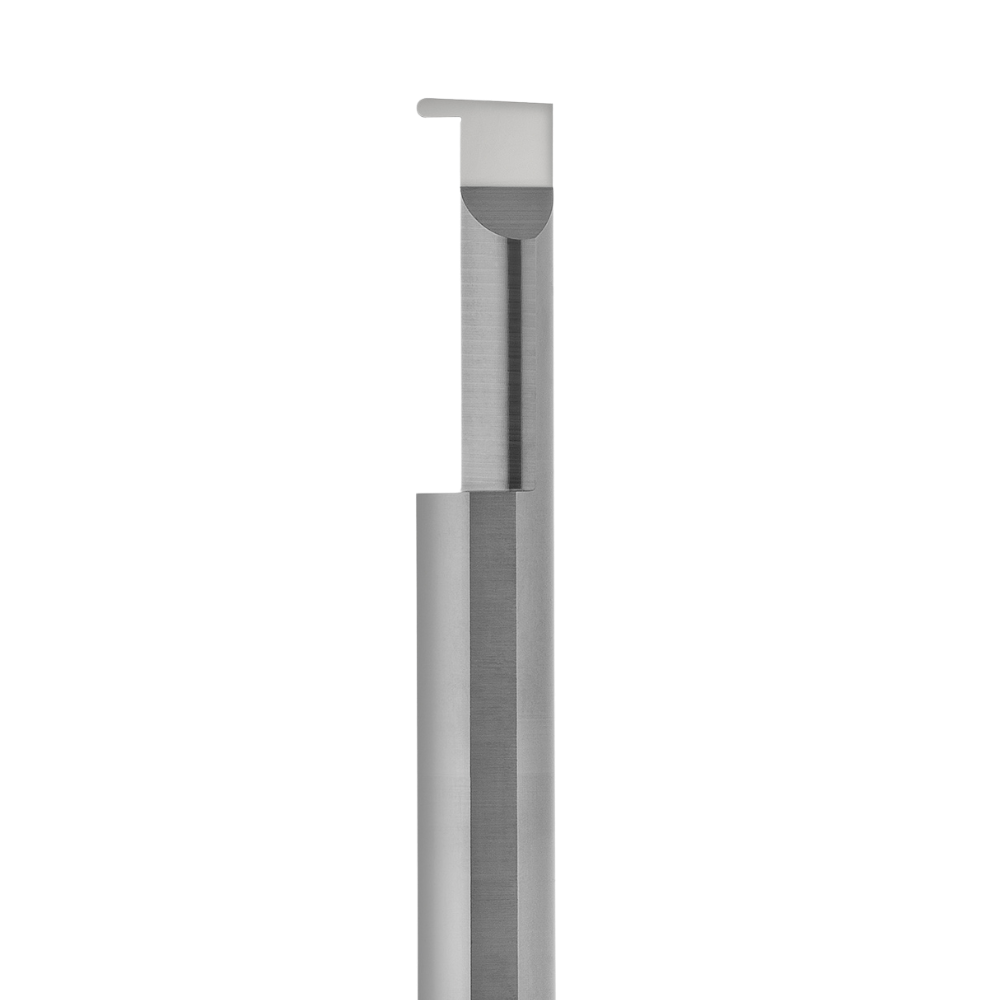

Full Radius

Groove Tools

Smooth radius grooves for sealing features and form requirements.

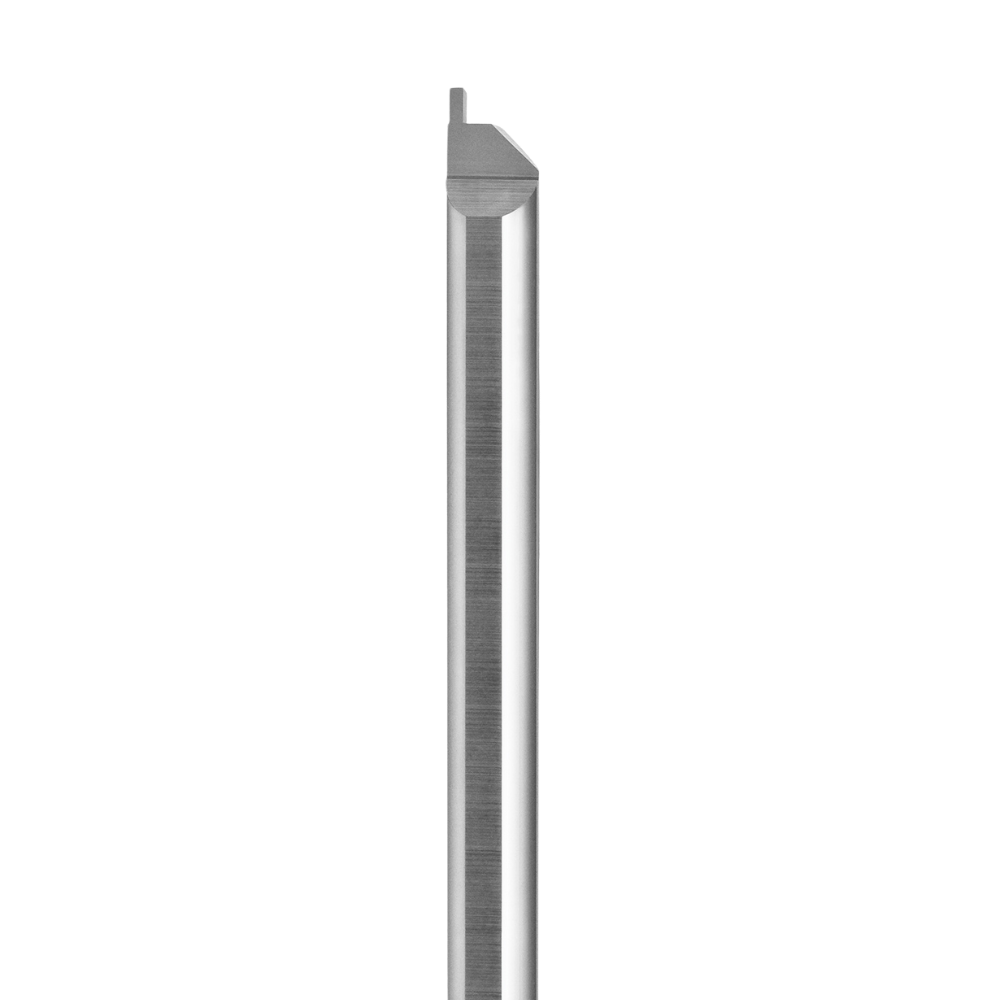

Face

Groove Tools

Accurate face grooves with strong wall finish and stability.

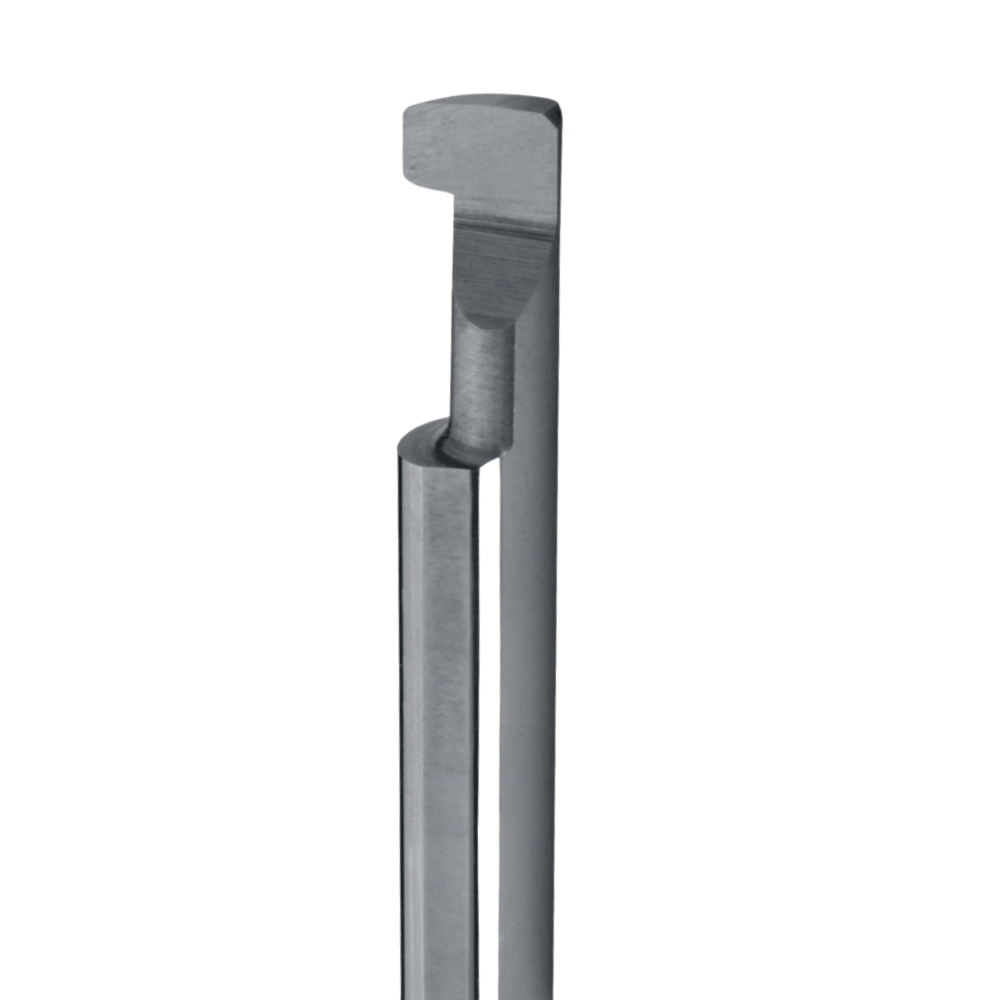

O-Ring

Groove Tools

Dial in O-ring grooves with consistent profile geometry.

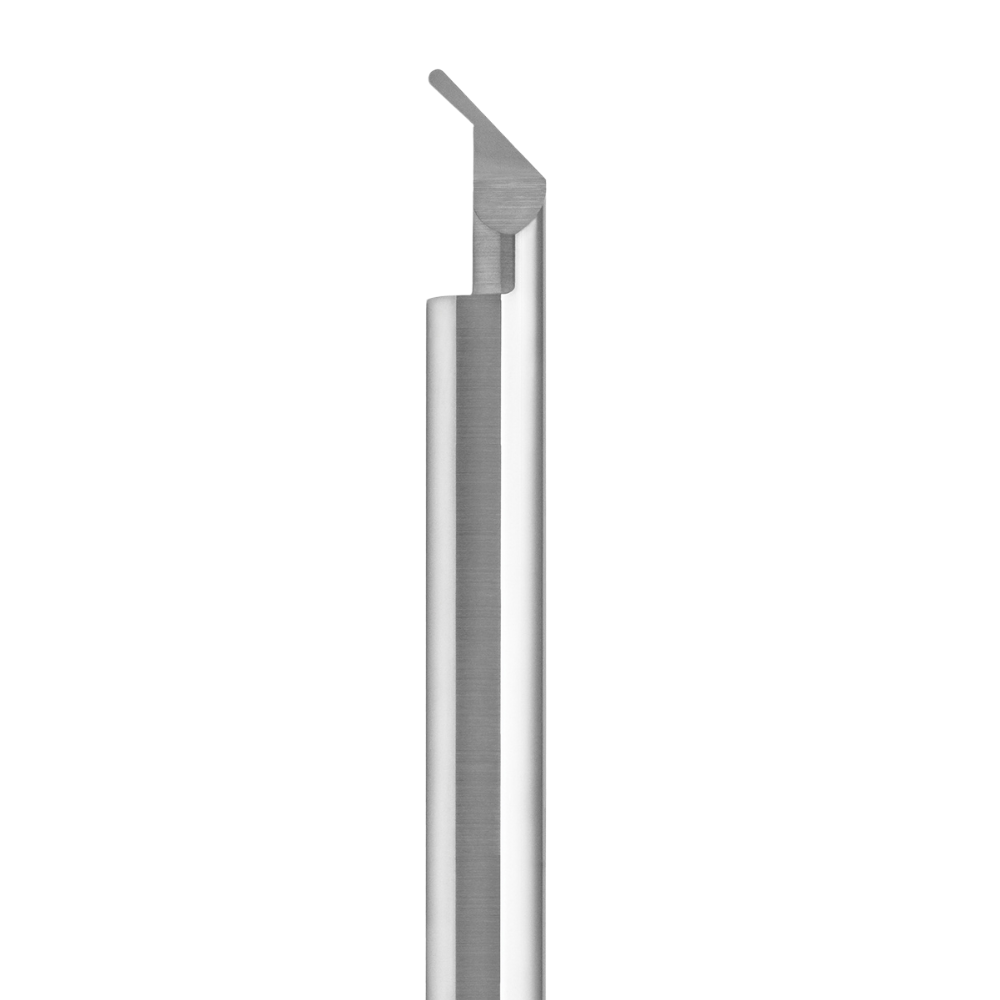

Undercut

Groove Tools

Reach undercuts and reliefs without compromising control.

Custom & Modified

Groove Tools

Get the exact groove form you need when standard tools aren’t an option.

What You Get With SCT

Consistent groove geometry

Grooves are unforgiving: width, depth, and wall quality all have to be right. Our grooving tools are designed to deliver consistent geometry so parts fit, seal, and function the way they’re supposed to.

Stability for clean walls and corners

Tool stability is everything in grooving. These designs prioritize rigidity and controlled engagement to help reduce chatter, maintain wall finish, and keep corners clean — even when the feature is tight.

Tool life that holds up in production

Reliable performance isn’t just about the first cut. With carbide built for demanding applications and geometries intended to reduce cutting pressure, you get longer usable life and less variation over time.

Not sure which groove style you need (O-ring vs full radius vs retaining ring)? Start with the “Choose your grooving tool type” tiles, or reach out for help.

Support That Starts

Before the Cut

We don’t just sell grooving tools. We back them with the knowledge and support you need to meet spec and machine with confidence. Whether you’re refining your grooving tool strategy or need speeds and feeds for a current job, these resources are here to help.

DXF and STEP File Downloads. Get CAD-ready files for faster CAM programming and toolpath simulation.

Explore Our Tech Support Pages. From troubleshooting tips to feeds and speeds guidance, our Technical Support hub is your go-to resource.

Still need help? Our in-house engineers are just a click away. Submit a question and we’ll get back to you quickly.