Boring Bars

Dial in size, finish, and control with American-made carbide boring bars built for repeatability across general purpose and specialty geometries.

Choose your boring bar type →

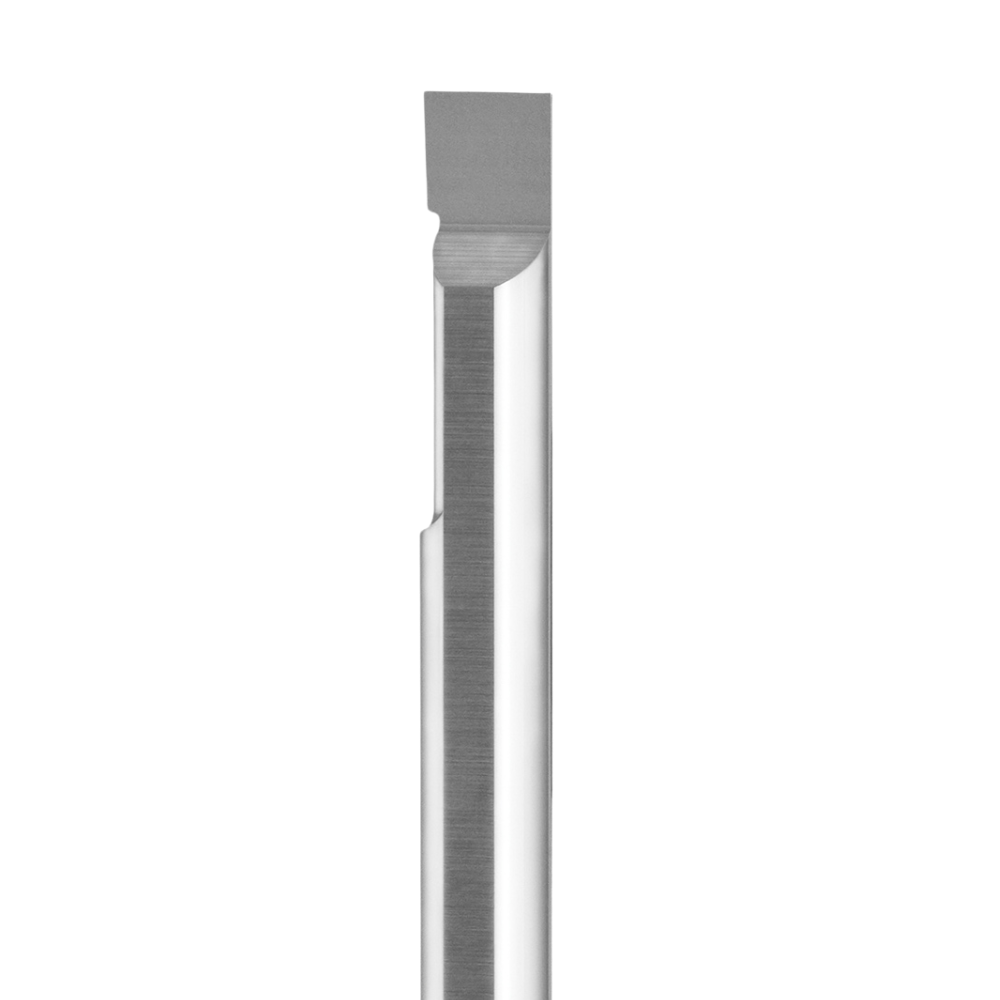

Boring Bars

General-purpose boring for everyday diameters and materials.

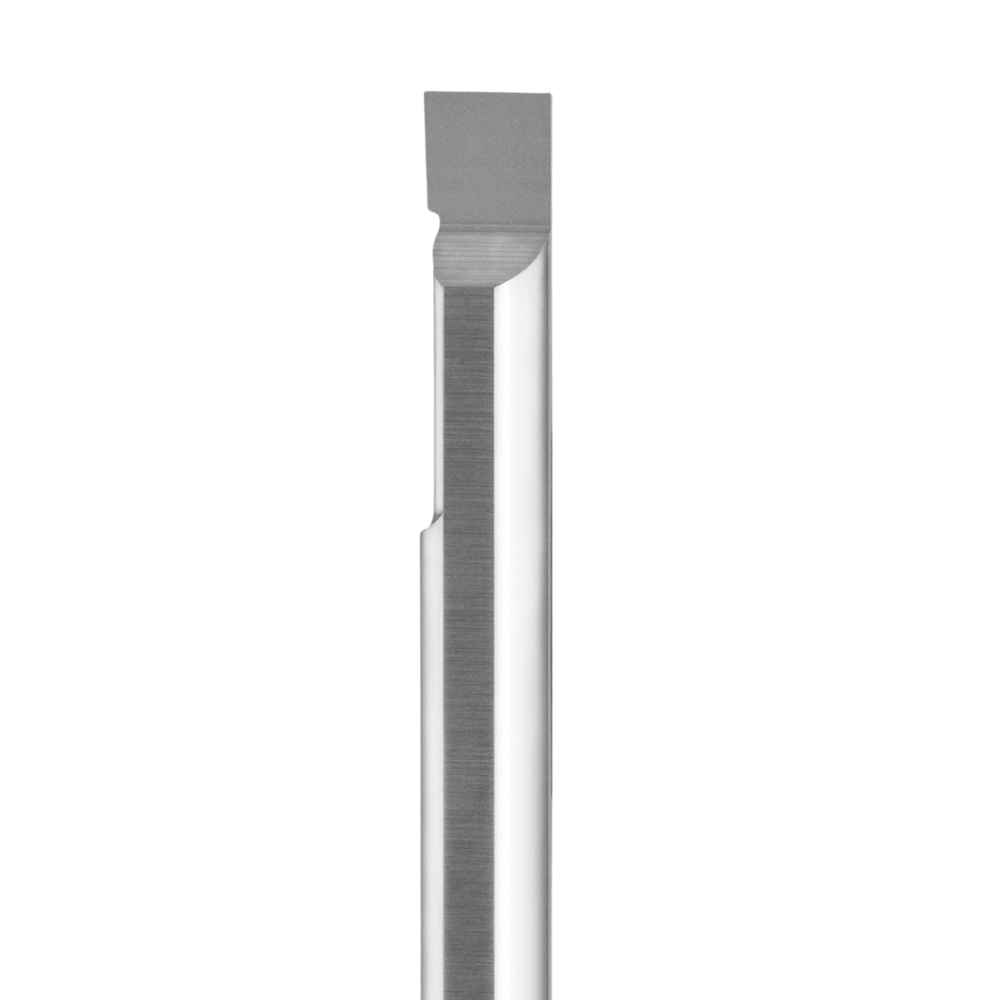

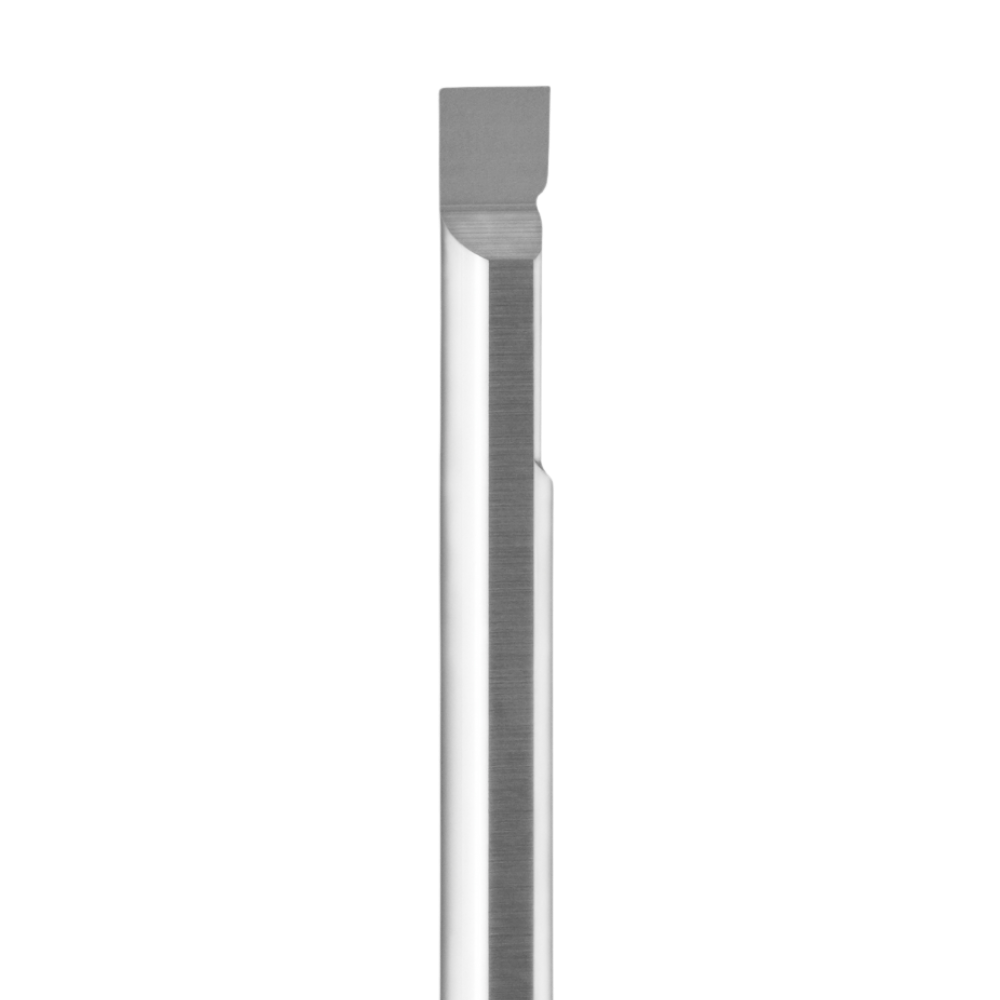

Radial Relief

Boring Bars

Reduced contact for cleaner finishes and less rubbing.

Radius

Boring Bars

Blend radii and profiles without hand finishing.

Helical Back Rake Boring Bars

Improved chip evacuation and lower cutting forces.

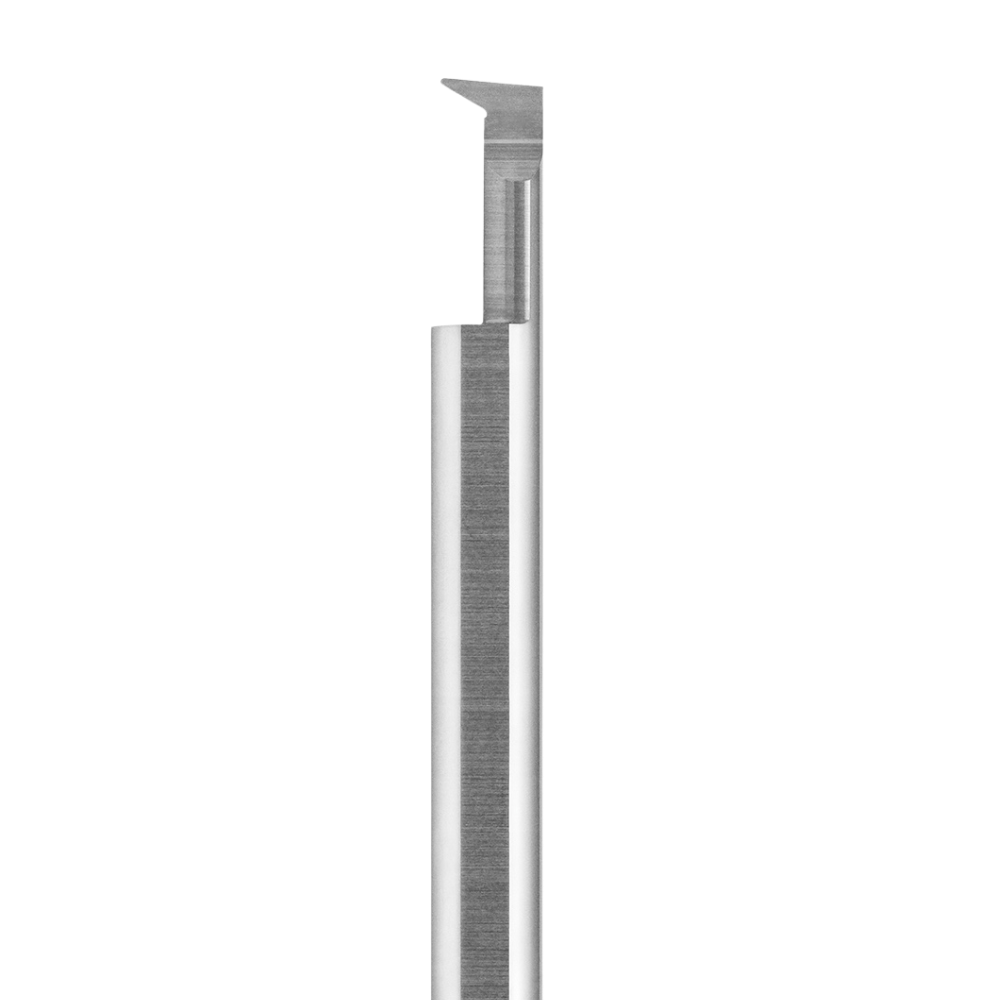

Profile

Boring Bars

Complex internal profiles with predictable form control.

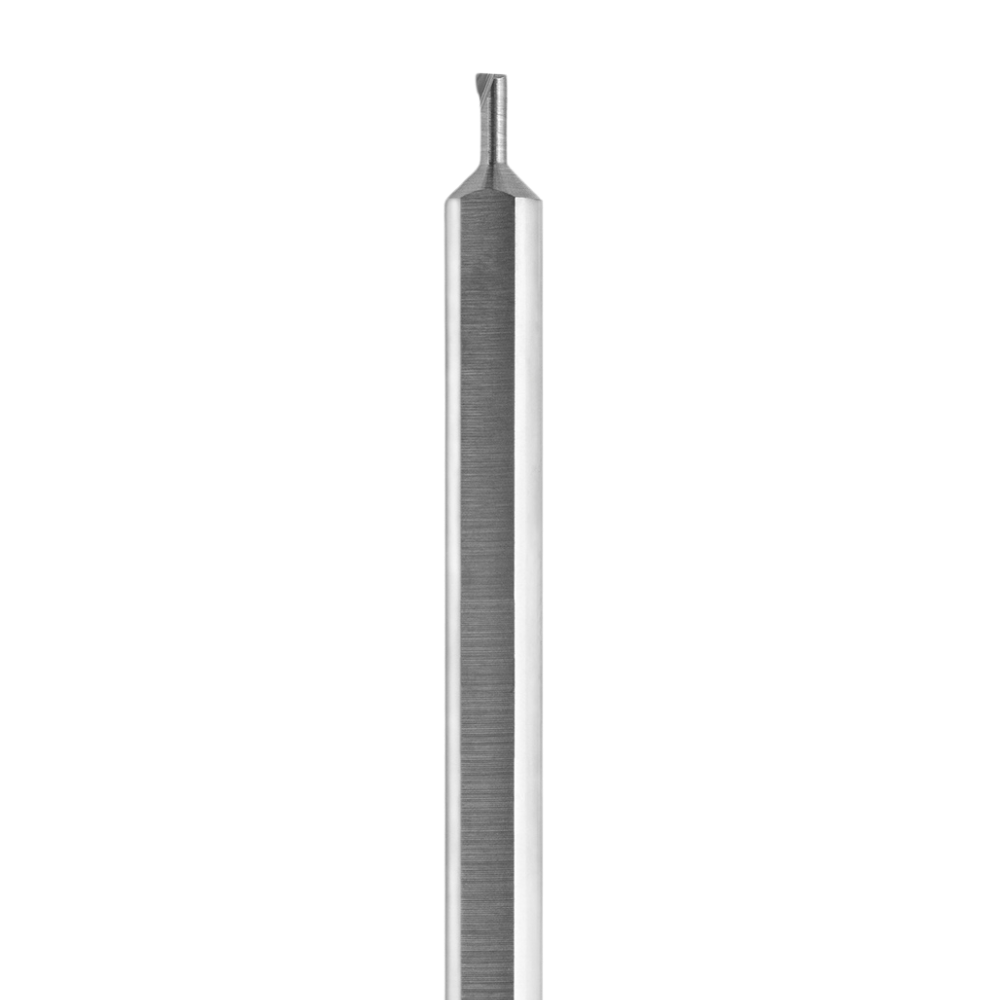

Mini

Boring Bars

Tight spaces and small bores without sacrificing rigidity.

Helical

Boring Bars

Balanced geometry for consistent performance across bores.

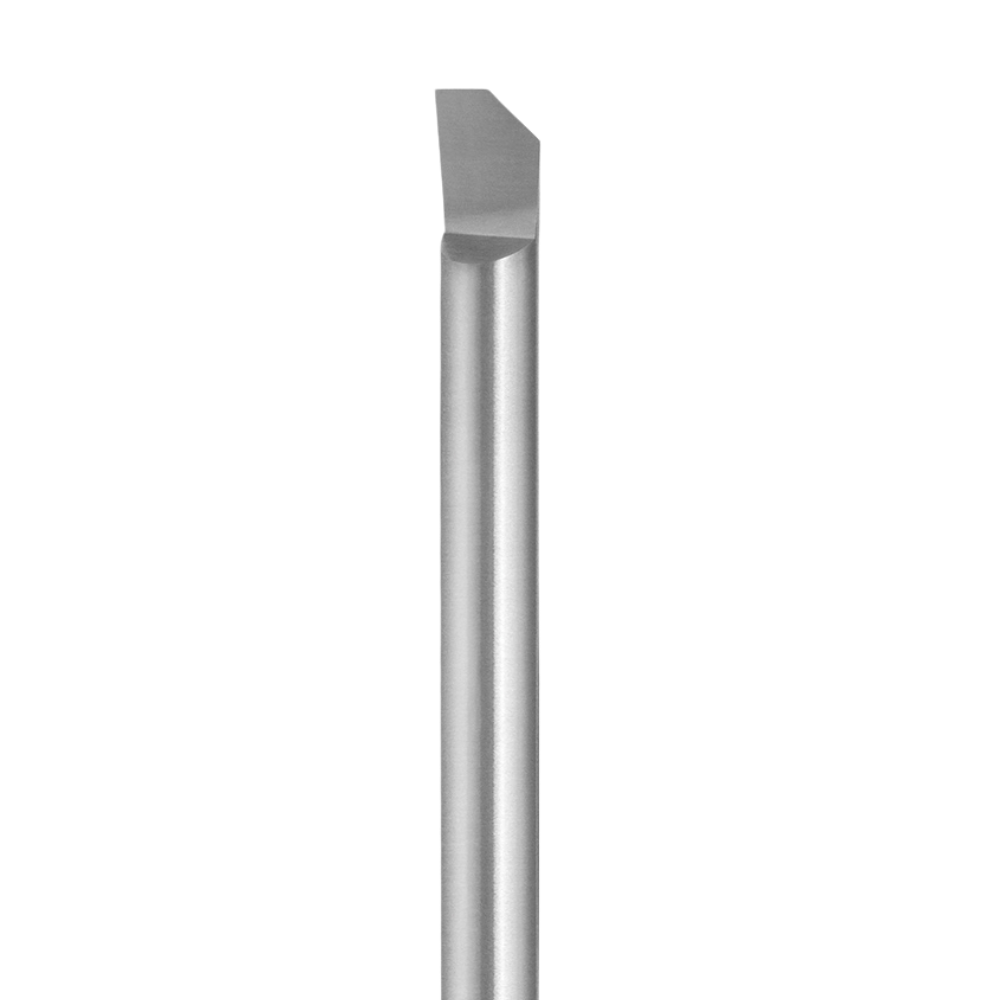

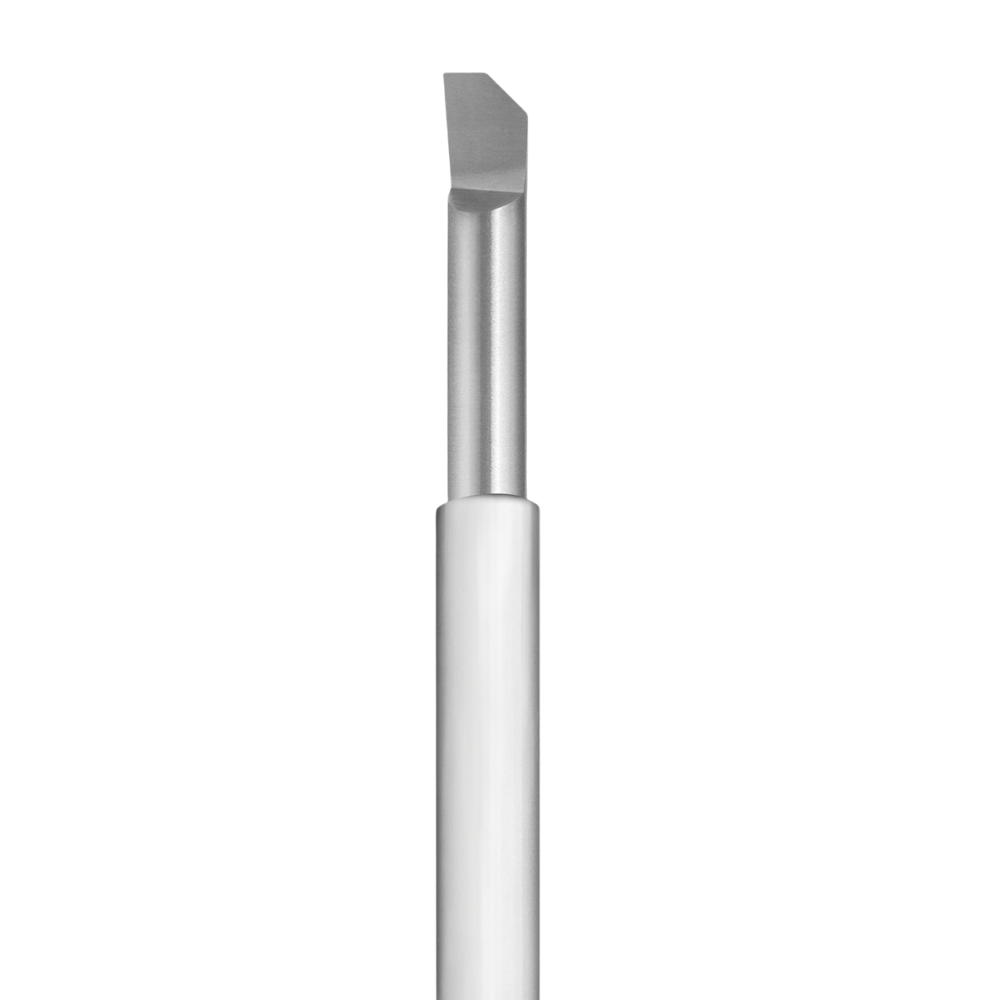

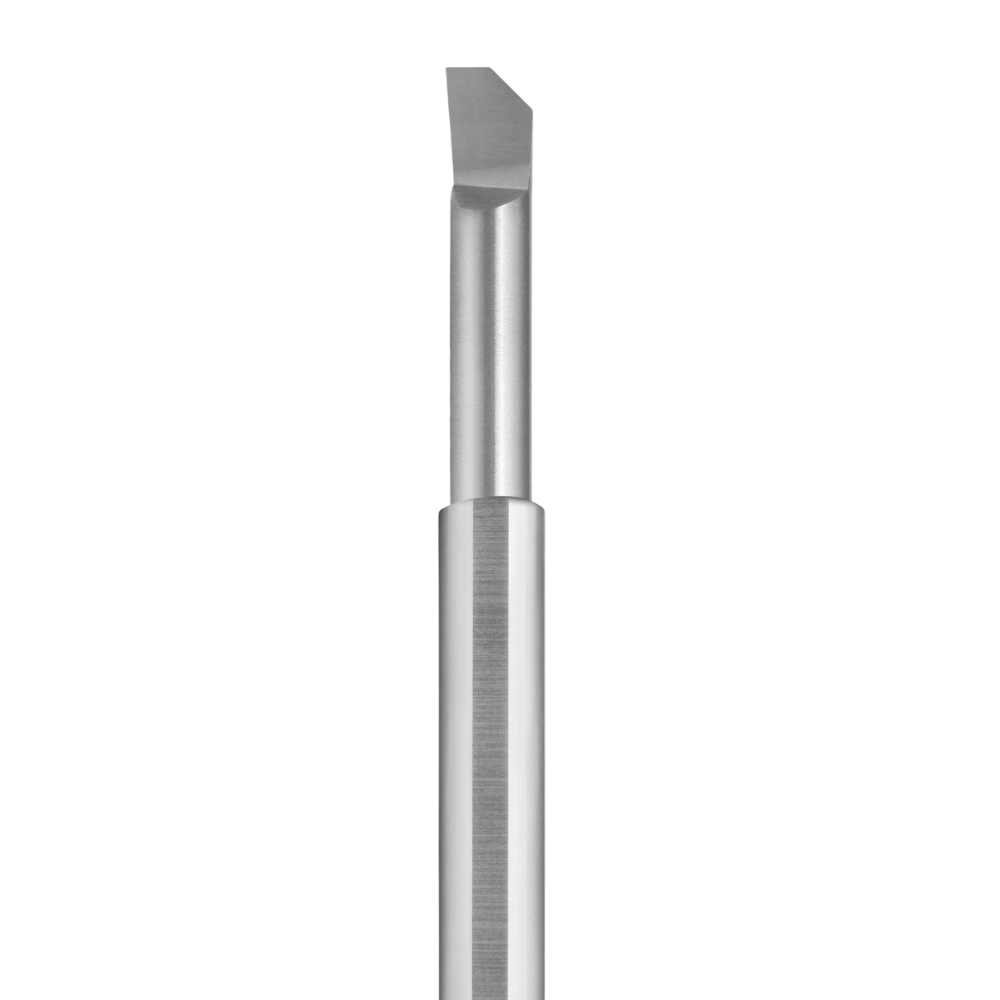

Back Chamfer

Boring Bars

Chamfer and deburr hard-to-reach features from inside.

CBN & PCD Tipped Boring Bars

High-wear applications and abrasive materials.

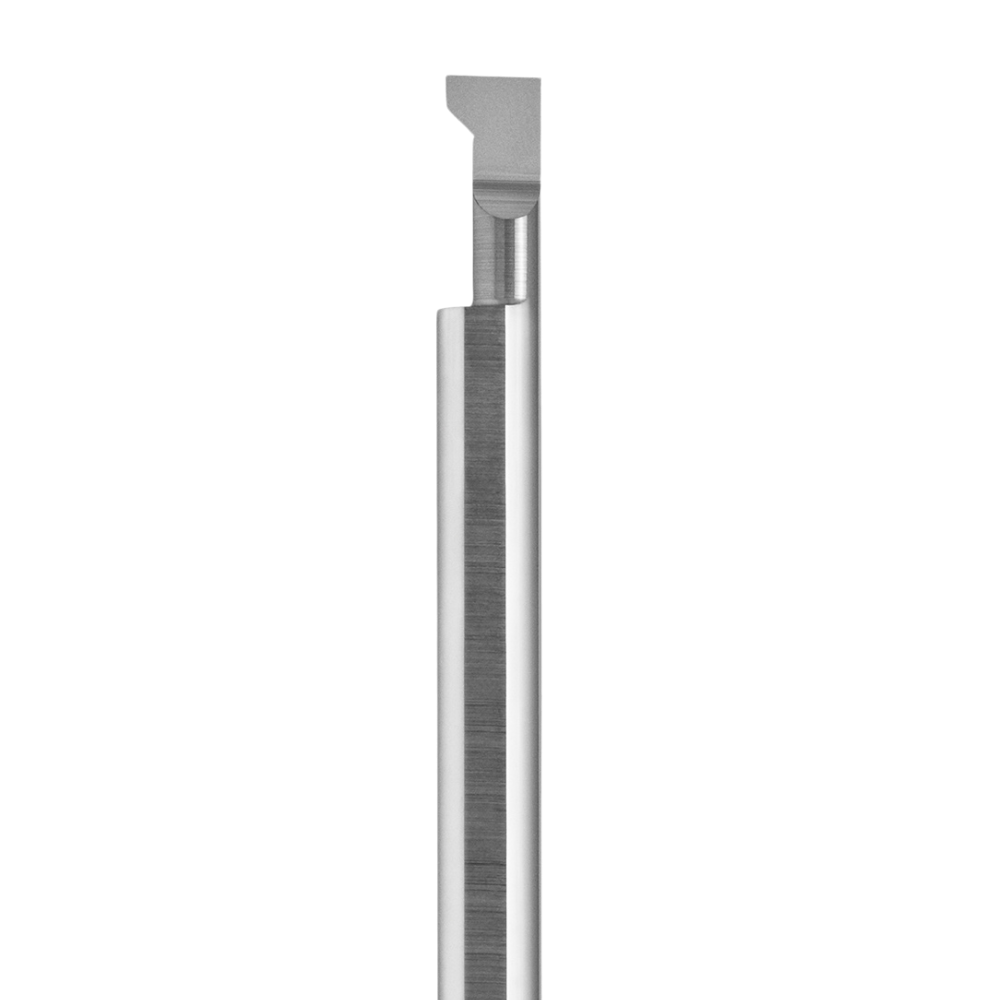

Helical Back Rake without Flat

Smooth entry and finish with a cleaner profile.

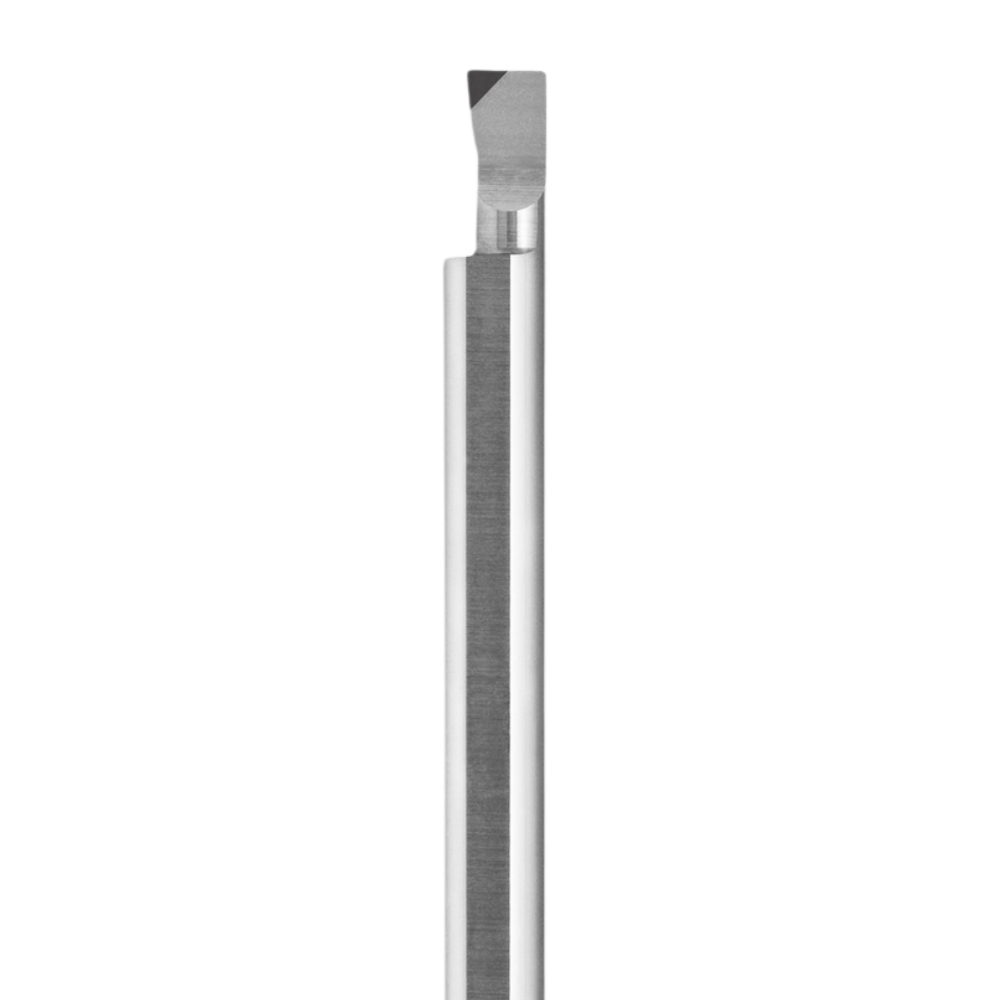

Helical Back Rake

with Flat

Extra stability and control where you need it.

Left Hand

Boring Bars

Left-hand orientation for setups that

demand it.

What You Get With SCT

Size control you can trust

Hold size and position with boring bars designed for stability and repeatability. When offsets matter, you want predictable engagement and consistent results from the first part to the last.

Better finishes with less rubbing

Choose geometries that reduce contact and control how the tool enters and exits the cut. The result is cleaner wall finishes, less chatter, and fewer “mystery marks” that show up at inspection.

Chip control that keeps production moving

From helical and back-rake options to relief styles, these tools are built to manage chips and reduce cutting pressure. That means fewer interruptions, more confidence at higher feed rates, and more consistent cycle times.

Need help selecting the right tool? Our team can recommend the best boring bar style based on bore size, material, and finish requirements.

Support That Starts

Before the Cut

We don’t just sell boring bars. We back them with the knowledge and support you need to meet spec and machine with confidence. Whether you’re refining your boring strategy or need speeds and feeds for a current job, these resources are here to help.

DXF and STEP File Downloads. Get CAD-ready files for faster CAM programming and toolpath simulation.

Explore Our Tech Support Pages. From troubleshooting tips to feeds and speeds guidance, our Technical Support hub is your go-to resource.

Still need help? Our in-house engineers are just a click away. Submit a question and we’ll get back to you quickly.